In Adelaide I made a lot of prototypes PCB's and filled up filing cabinets and shelves with them. Some had value to others and I sold them on Tindie and CrowdSupply. For the last year I have been hanging out in Kenya working at Lori. The output in terms of open-source hardware has taken a back seat compared to proprietary company code (we did release one open-source piece of ETL code).

This is near the end of my 3-month stint in Kenya and I decided to run an experiment in the feasibility of designing and assembling prototype batches of PCB's for an energy monitor ASIC I have been meaning to try out - the CS5490. This is a super low bar for a test run. The IC has very few dependent components and large pin pitch making it ideal of teaching manual SMD soldering.

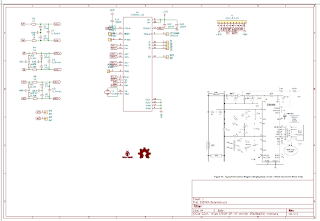

PCB Design

Once the goal was set I broke out KiCAD and spent a night and a Sunday churning out a basic breakout board. The PCB Design and BOM are published here.

Order PCB

The harder part begins once the PCB design is done. Actually making this a physical reality in Kenya. I placed the usual order via PCBWay. A few days before Christmas before I went off to a round a country drive with some friends ( awesome content for another post). The shipping would be from Shenzhen via DHL. The logistics promises arrival by the 28th December.

Order Parts

The BOM for the design is not super complex either. Mouser covers the Kenya region. However there is no option for free DHL for orders over $60 which I get in Australia. I will be in Kenya only till the 20th January and the streets have no numbers or postcodes, which makes ordering via snail mail for any international shipping simply not fit the address template most places have. Perhaps global addressing via plus codes will become reality in future eCommerce systems. Mouser shipped the parts out of Texas immediately, I ended up paying more on shipping than for parts. The customs magic was yet to come.

Clear customs

Any packages with value below $1000 sail through customs in Australia. The Kenyan government will lose out on significant revenues if they followed this practice. On the flipside young engineers with limited resources are being stifled in self-driven learning and experimentation by this practice. I got a detailed/itemized bill from customs via DHL which ended up being the same cost as PCB + shipping for PCB's and around 20% of the cost of the parts. See file here for details and breakdown.

Source tools and materials

Thankfully this bit was much easier with a couple of local soldering iron , jumper wire and tweezers suppliers filling the gap. The ball was dropped by Fargo in delivering the stuff I ordered online again due to the addressing snafu, they attempted 5 deliveries to the wrong place before I had to redirect to the office address where a lot of parcels are received. I can recommend Nerokas and Ktechnics for getting parts in without hassle. Again better last mile logistics would have made things faster. I ended up attending the assembly meetup without the proper tools.

Find assembly space

To avoid annoying my landlord with solder fumes and messy paste workbench I started looking for a place to get together with a few interested parties and assemble the boards (at least one). I ended up starting an open-source hardware meetup and getting some Mang'u engineers together to hand solder the parts.

1 PCB - x3 assemblers and a gas stove from a local shop. pic.twitter.com/S09EZJbZ5k— Tisham Dhar (@whatnick) January 5, 2019

Test and publish drivers

Finally this Sunday I have put together some basic micropython code to read registers from the CS5490 over serial and display them in a micropython notebook. Nothing production ready but proof that the PCB design and assembly worked as expected and we can achieve custom products here, with a lot of bureaucracy and false starts.

I am happy to meet more people designing and building open-source hardware in Nairobi and hear about their experience.

No comments:

Post a Comment